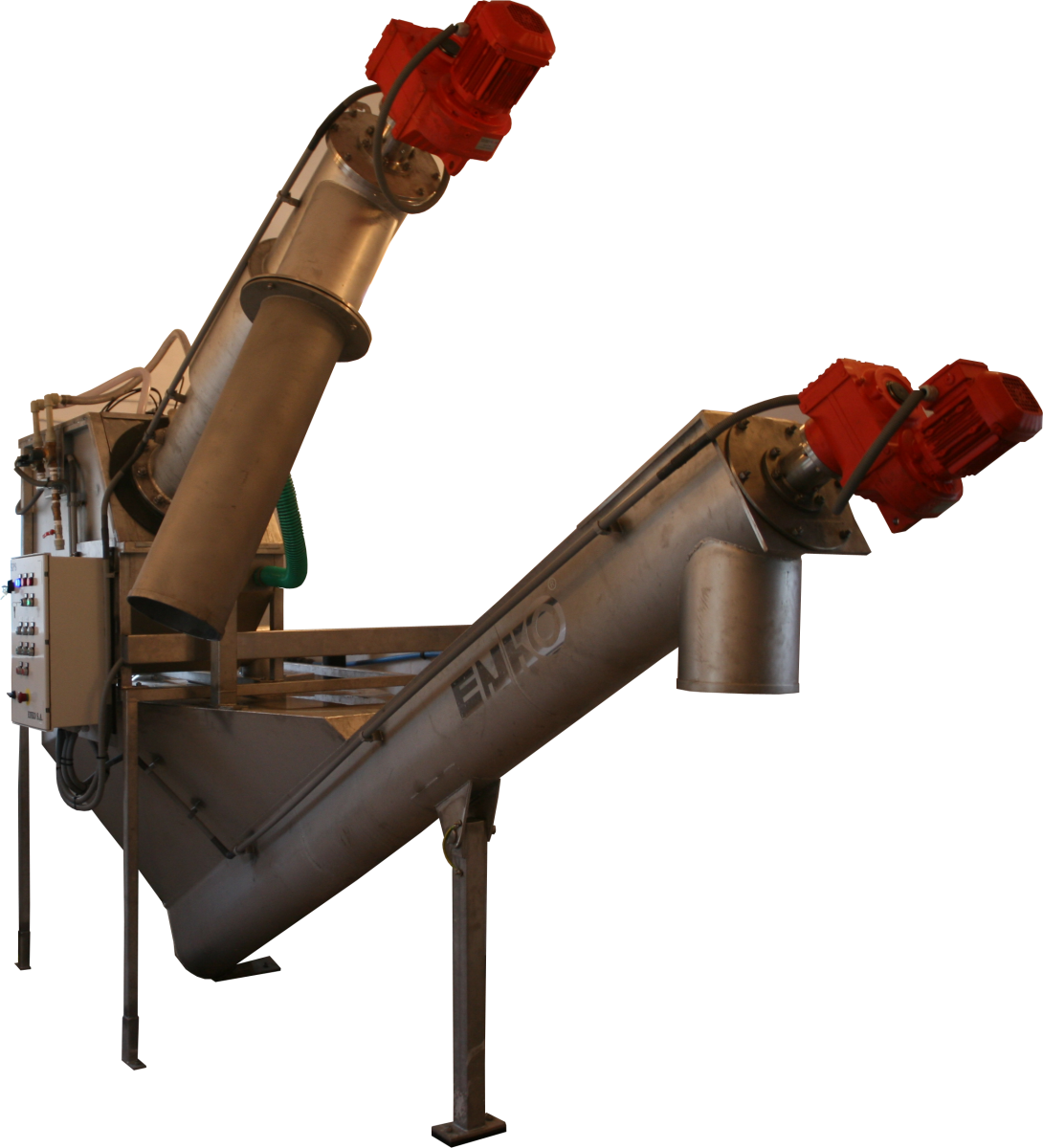

Compact screening and sand separation device type SPS

The interlocked device for mechanical removal of screenings and sand consists of a spiral screen for separating screenings, integrated with the screenings dewatering press and a sand separator for removing sand. The entire purification process is closed and airtight.

-

the device allows for effective simultaneous removal of screenings and sand

-

screenings and pen separation process is closed and hermetic

-

screenings dehydration and concentration to approx. 40% of dry matter

-

fully automatic device

-

the device is made entirely of acid-resistant steel

-

small dimensions

Additional information

Additional information

- The device has a control cabinet, driver and software.

- All parts in contact with the medium are made of stainless steel 1.4301 or equivalent (except fittings, actuators and bearings), pickled in an acid bath.

- Hermetic and tight device casing, made of stainless steel 1.4301 with removable elements for service works.

- No contact of running bearings with sewage.