Screens KSE/KHS/KHZ/KHP/KKE/KRE

-

Separation and dehydration of screenings

from the waste water that flows in -

Optimal adaptation of the screen type

to individual operating conditions - High capacity

-

Compact construction with possibility

of process containment -

Possibility to extend the system with equipment

for screenings flushing, grinding , pressing and

dehydrating

Screens are universal devices designed to separate solid pollutants (screenings) from waste water.

Using screens, you can reduce the likelihood of clogging of some equipment in waste water treatment plants, such as pumps, aerators, etc.

Screens have a variety of uses in waste water treatment plants, as well as in fish, meat, paint, paper, textile industries, dairies, pumping stations and others.

Dimensions of the screens manufactures by ENKO are tailored to real flows and conditions of each facility.

The screens can be installed in ducts of various sizes. Screenings are removed from the bottom, moved above the edge of a duct to a level allowing their removal into containers or transport equipment.

Our screens can be equipped with different filtering element (system) construction.

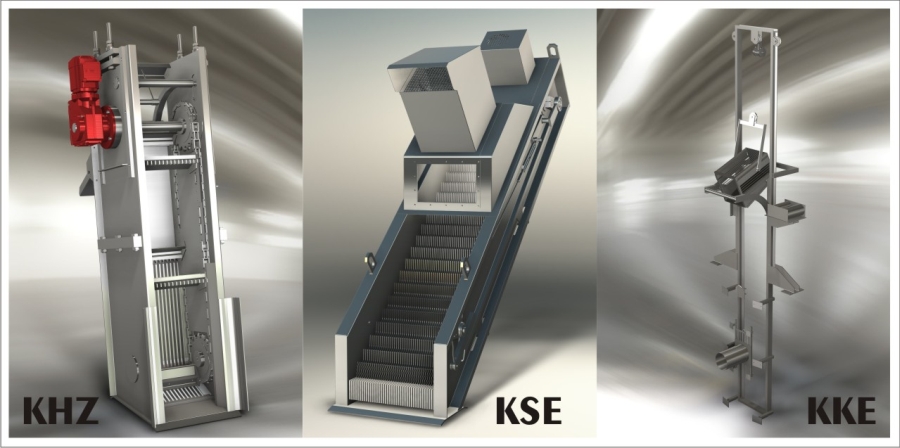

Types of mechanical screens:

- step screen type KSE – where the filtering element is a grating (movable or immovable),

- hook screen type KHS – where the filtering element is a movable rod grating, and the scraping element is a hook-scraper system,

- scraper scrren type KHZ – where the filtering element is an immovable grating, and the scraping element is a scrapers system,

- panel screen type KHP –where the filtering element is a perforated panel tape

The process:

In the purification process waste water flows through the filtering system. The system captures any floating substances. After that, the cleaning system moves the separated solids into the exhaust system, and the waste water

without solids flows into further steps of purification. Collecting screenings from the grate and their transport is done automatically.

Partly dehydrated screenings are transported up to the feeding hopper, where they are thrown off to a container or transport equipment (e.g. conveyor, press).

The grate can be equipped with a thermal housing and heater, which allow it to operate at low temperatures, or a ventilation system can be connected in order to maximize the wastewater treatment process containment.

The system can operate in automatic or manual (service) mode. Release is done automatically by a level sensor (a difference system for levels before and beyond the grate can be installed) or by a signal from the master device.

Materials:

Screen design - cleaning and separating systems are made of stainless steel or plastic. The material provides resistance against aggressive activity of waste water.

Each element (i.e. filtering system, cleaning system, gear-motor and housing) are mounted to a solid welded frame, which is also made of acid-proof steel.

Types of screens:

- step screen type KSE

- hook screen type KHS

- scraper screen type KHZ

- panel screen type KHP

- basket screen type KKE

- manual screen type KRE